This website is no longer maintained. Its content may be obsolete. Please visit http://home.cern for current CERN information.

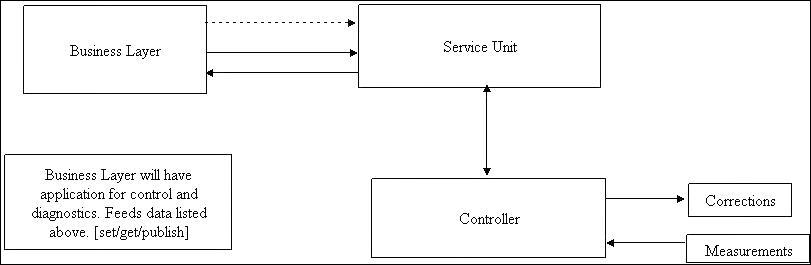

Division of real time functionality between service unit and controller. Service unit interacts with business layer to get required data for controller. Imagines SU and controller running on separate RT machines. FESA suggested and nominally agreed as being the appropriate framework under which to develop these components.